roduct Name: Plastic laboratory fume cupboard exhaust fan

Model: MPCF-250-F4T

Specification

| 1 |

Materials |

PP impeller + PE spiral case+100% Copper motor |

| 2 |

Color |

white spiral case + blue motor+ blue bracket |

| 3 |

Diameter of intlet |

Φ240 |

| 4 |

Diameter of outlet |

Φ240 |

| 5 |

Power |

1500W |

| 6 |

Power supply |

380~460V/50~60Hz available |

| 7 |

Max Airflow |

4500 CMH ( Cubic Meters per Hour ) |

| 8 |

Max Pressure |

550 Pa |

| 9 |

Net weight |

32.0 KGS |

| 10 |

Gross Weight |

34KGS |

| 11 |

Packing details |

Carton, Size: 58*49*66CM |

| 12 |

MOQ |

1 Piece |

| 13 |

LOGO |

Please send me your design, we can print it on fan |

| 14 |

OEM accepted |

Yes |

| 15 |

Sample time |

normal 5 days/ special 15 days |

| 16 |

Certification Availalbe |

CCC, CE, ROHS, ISO9001 |

| 17 |

Production capacity |

1000 per month |

| 18 |

Payment items |

100% payment before manufacture <5000USD

30% as deposit, 70% before shipment > 5000USD |

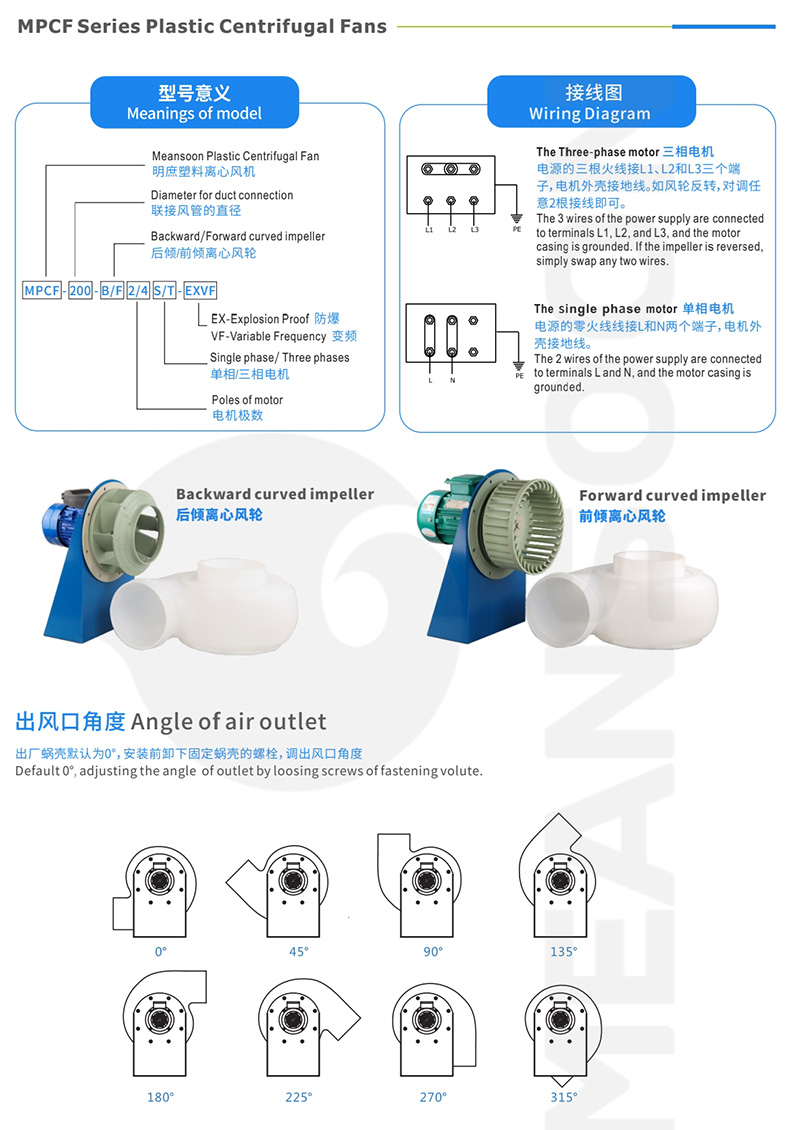

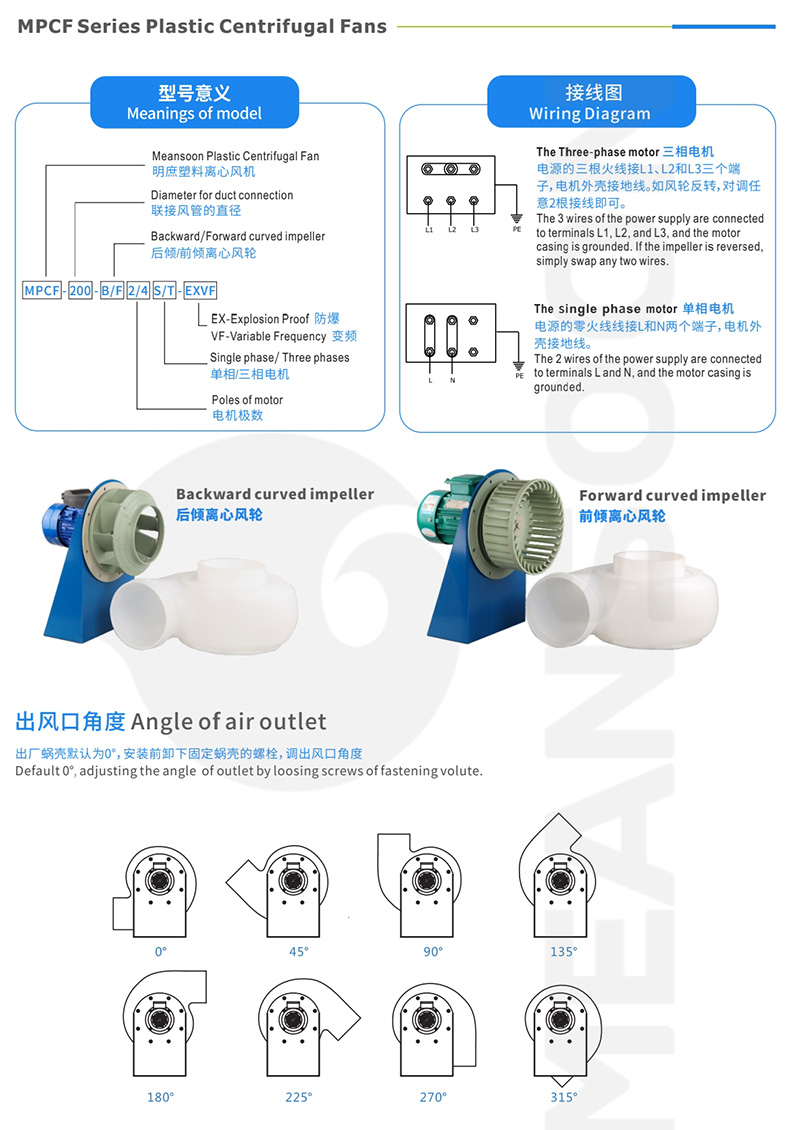

PLASTIC LABORATORY FUME CUPBOARD EXHAUST FAN

GENERAL DESCRIPTION

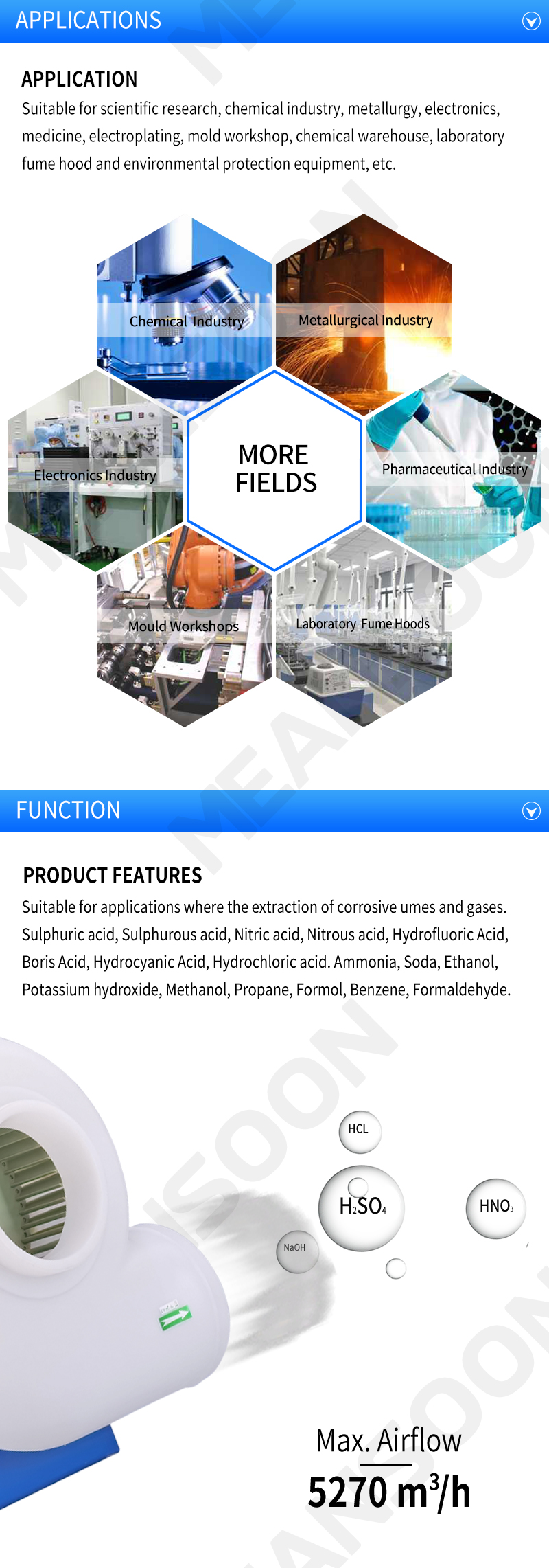

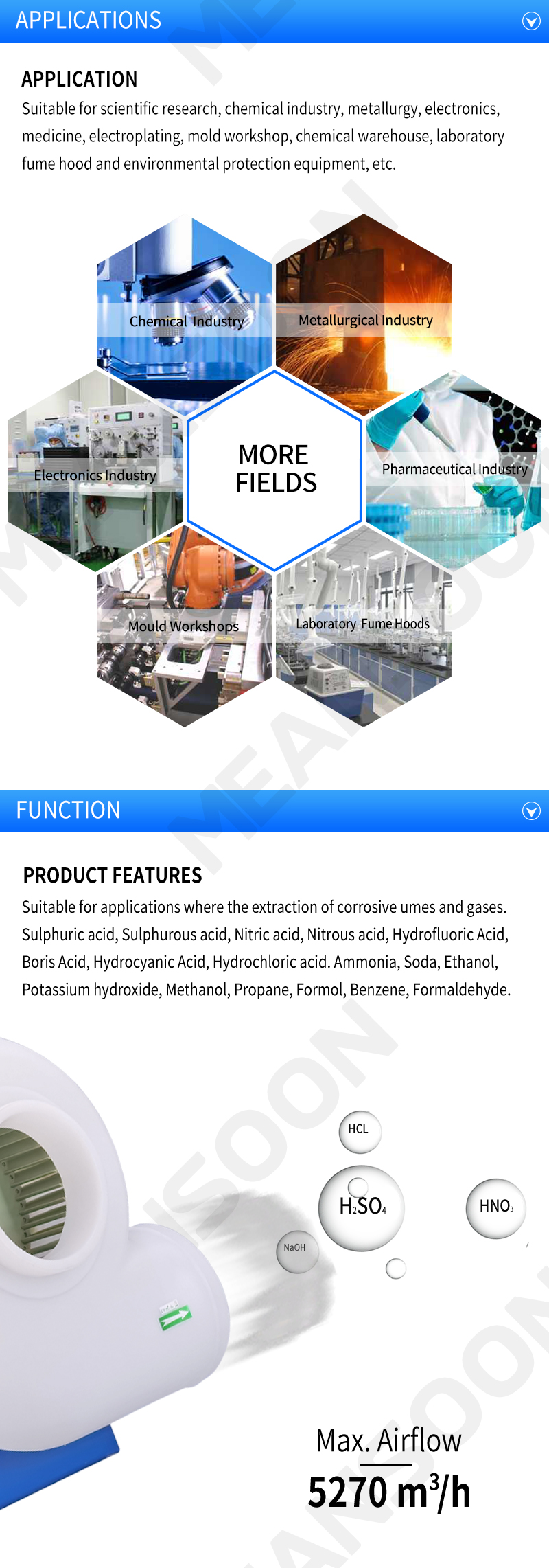

Plastic laboratory fume cupboard exhaust fan is particularly designed for conveying corrosive vapours and smokes, also with high humidity level and with maximum emperature of 60ºC.

Suitable for applications where the extraction of corrosive fumes and gases:

Sulphuric acid, Sulphurous acid, Nitric acid, Nitrous acid, Hydrofluoric Acid, Boris Acid, Hydrocyanic Acid, Hydrochloric acid. Ammonia, Soda, Ethanol, Potassium hydroxide, Methanol, Propane, Formol, Benzene, Formaldehyde.

APPLICATION

The MPCF series of Plastic laboratory fume cupboard exhaust fan with backward curved impeller provide good characteristics of low noise and high efficiency, which often are applied in laboratory, fume hood, fume cupboard, chemical storehouse, electroplating factory, medicine factory, muould factory, Electronic workshop and metallurgy for exhaust ventilation.

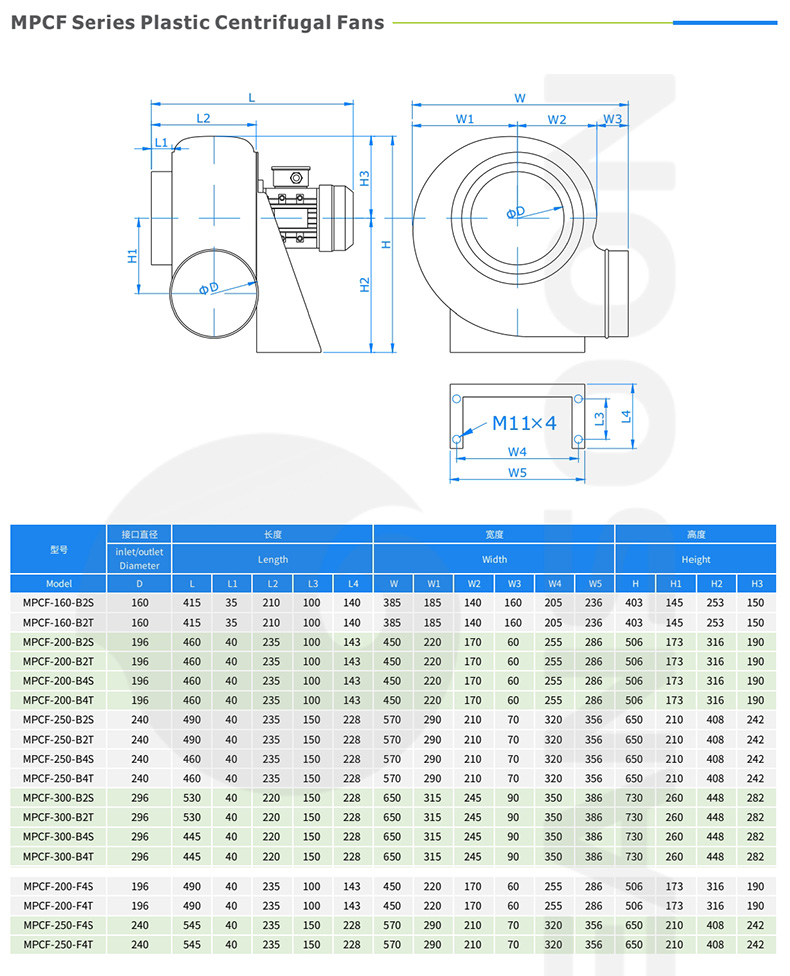

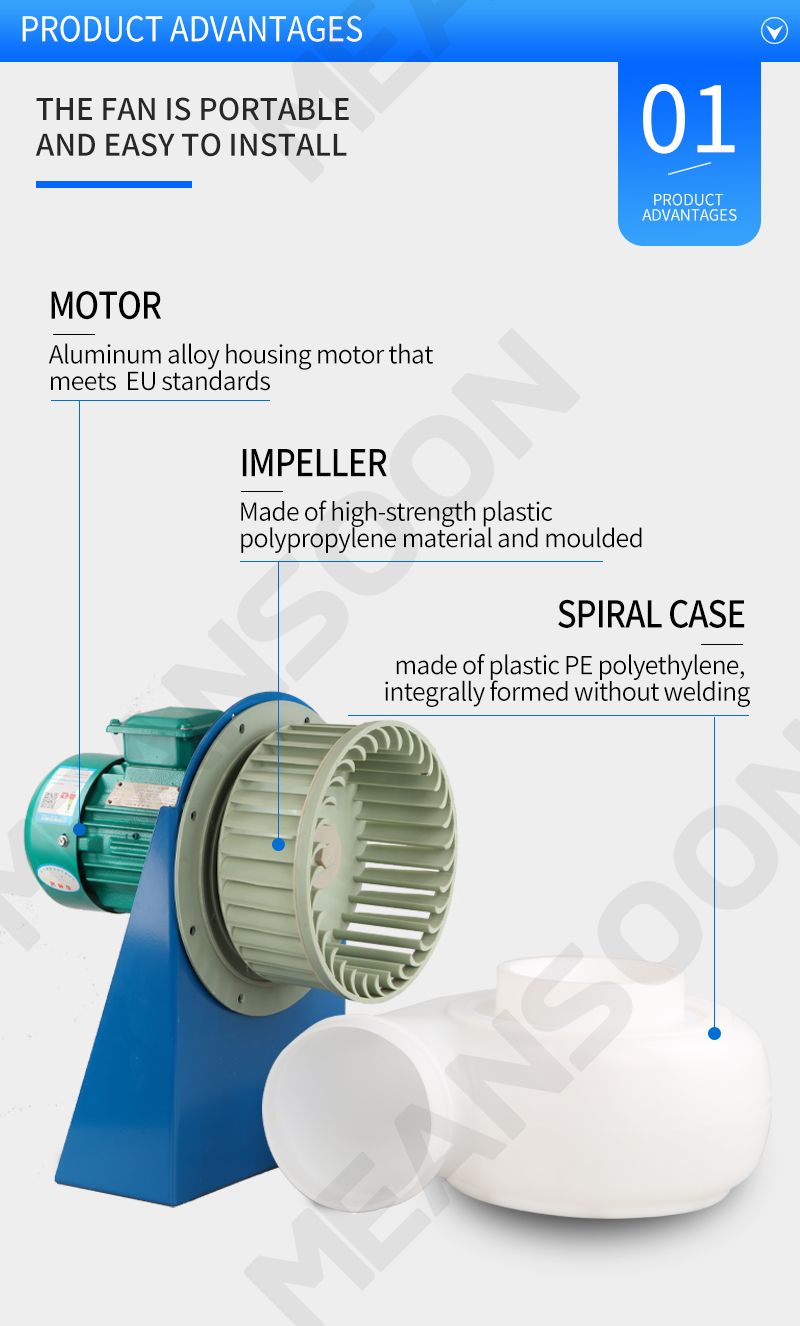

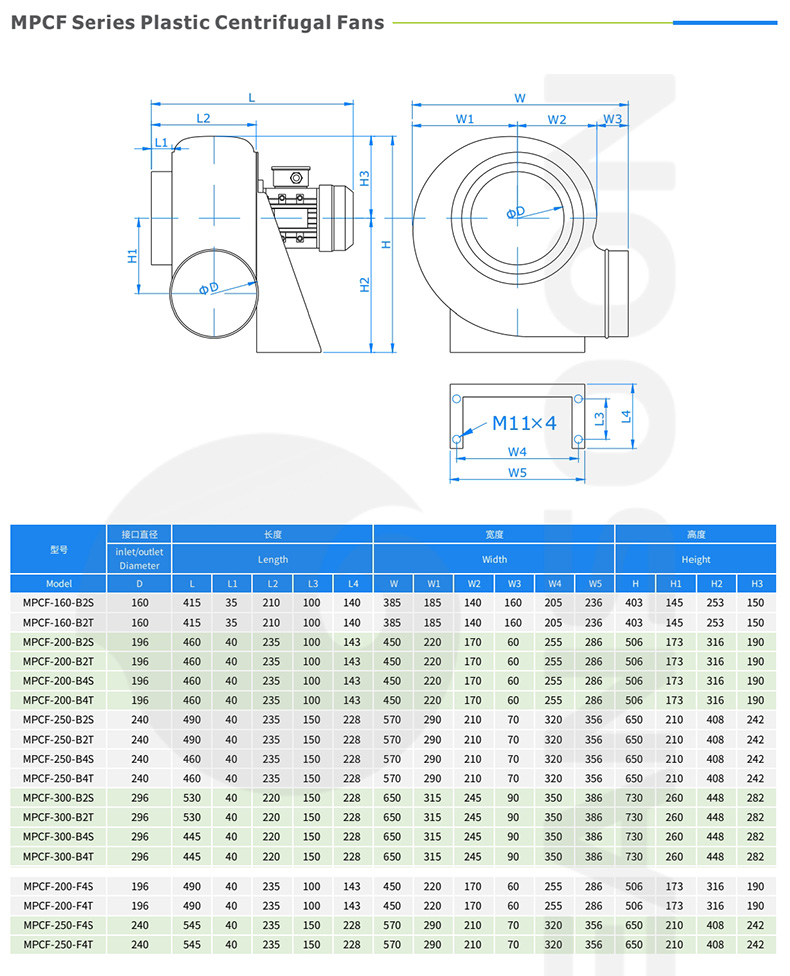

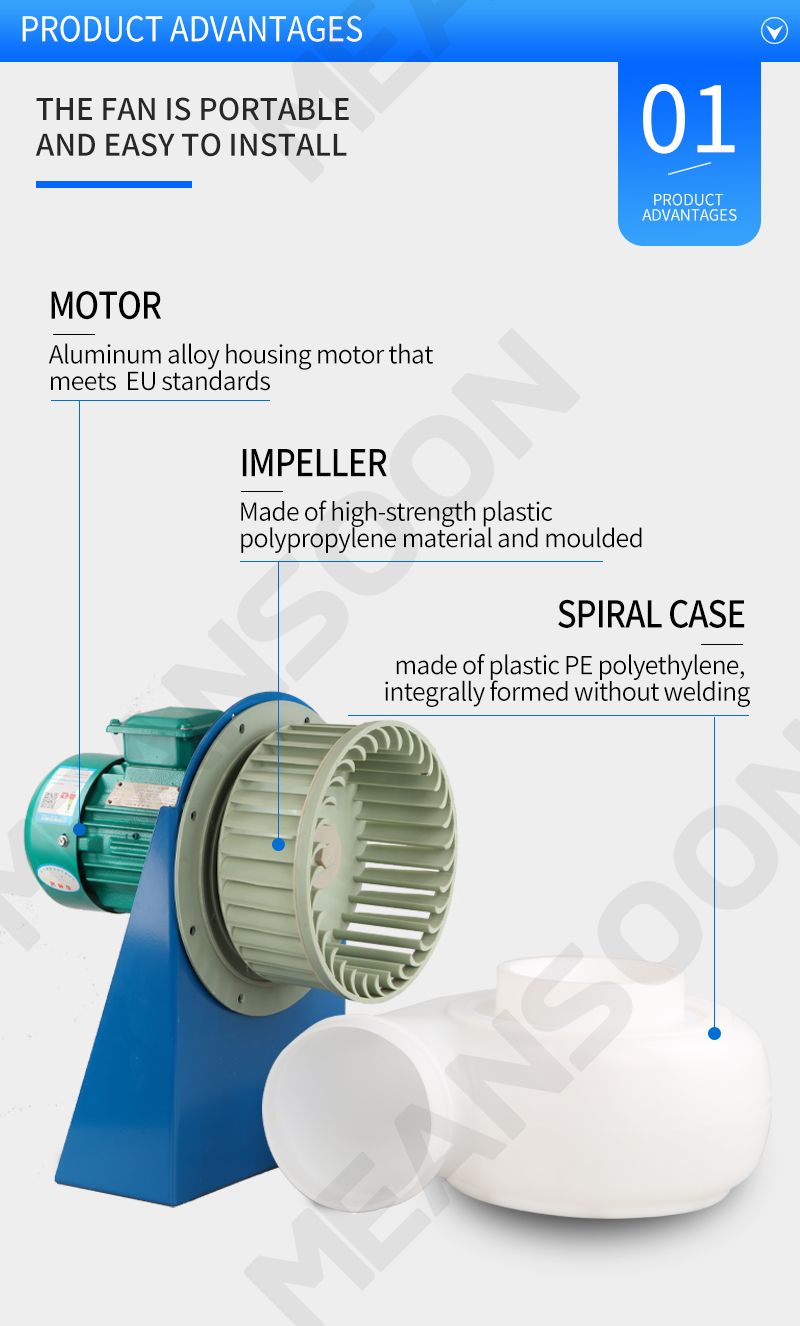

SPIRAL CASES

The spiral case is made of polyethylene(PE) plastic. Reversible and rotable to any the 8 standard discharge positions by 45°increments. All fan is with mounting bolts and nuts in 304 stainless steel.

Inlet/outlet are round with standard size: 160, 200, 250, 300, which are good for plastic duct connection.

IMPELLERS

The impellers with backwrod curved blades are high efficiency made of polypropylene(PP) plastic are balanced dynamically

on balancing standard G2,5 according to DIN ISO 1940.

MOTORS

Direct driving, asynchronous, single or three phase, IP55, class F, B5 shape in 2-pole and

4-pole execution. Single speed: three phase 380 V-50/60Hz, single phase 220V-50/60Hz. Explosion proof versions in accordance with ATEX Directive for three phase models is available. . Motor is outside the airstream. All motors speed adjustable by variable frequency inverter drive.

MOTOR SUPPORT

metal stand constructed of epoxy coated in blue.

Sample charge

Sample charge

We already show the 1 piece price on the price list, and freight shoud be calculated as actual weight.

Advantages

1.Low MOQ: It can meet your need very well.

2.OEM Accepted : We can produce as your demands .

3.Good Service : We treat clients as friend.

4.Good Quality :We have strict quality control system .Good reputation in the market.

5.Fast & Cheap Delivery: We have big discount from forwarder (Long Contract).

Order Guide

We take great pride in our work and in the wide variety of products that we offer. We are

experienced in servicing the Asia market, European market and Africa market .Please be aware that

our production lead times depend on specific items and item quantities. Our success has been based

on our understanding of the demands. That's why we always ensure that every order is delivered on time.

Check below for more information on placing an order

| 1 |

Inquiry- You get professional quatation |

| 2 |

Customer confirm the prices, Lead time, Technical demands, Payment item etc. |

| 3 |

We send the Proforma Invoice with meansoon signature |

| 4 |

Customer make the payment for deposit and send us bank receipt (bank slip) |

| 5 |

we tell customer received payment, and arrange production and inform the estimated time |

| 6 |

Close to the end production, we inform custoer to make payment for balance |

| 7 |

Customer let their forwarder contact us to deliver the products for shipment. |

| 8 |

we provide all documents to customer for Customs Clearance, and other documents customer demands. |

| 9 |

Order can be finished when Customer received the goods, satisfied with them. |

| 10 |

Please feedback to us about quality, service, market feedback, suggestion, and we can do better |